For any commercial caterer, the installation of a grease trap to manage fat, oil & grease is of utmost importance in the day to day running of your site(s). Failure to do so can result in a range of problems, including blocked drains, pest infestations, fire hazards, bad smells, and even fines, site closures and prosecutions in more extreme cases.

The first step for any site to take is to ensure that your site has sufficient grease removal systems in place to handle the volume of fat, oil and grease discharged by the various appliances during the preparation and cooking of food. With recent surveys in major towns and cities in the UK showing that as many as 90% of restaurants have insufficient, or no grease removal system in place, the importance of this first step cannot be understated.

By failing to install and maintain a correctly sized grease trap, sites are playing with fire, risking expensive drainage call outs, due to blockages and contributing to the scourge of fatbergs, which plague sewers worldwide. If your site are found to have contributed to, or caused a blockage/fatberg in the sewer line, you run the risk of site closures, a fine, or prosecution by landlords and water authorities, who are keen to clamp down on the problem. While purchasing and maintaining a grease trap may seem like a costly expense for many sites, it is actually a money saving commitment, as site closures, fines and frequent blockages can rapidly dwarf the initial cost of getting a grease trap fitted.

Although many sites will already have a grease trap fitted, this does not mark the end point of a site’s grease management responsibilities. When having a grease trap fitted, sites should ensure that the unit specified is suitably sized to handle the volume of waste entering into the system. Grease contractors should use a sizing calculation to determine what size of grease trap is required, which will typically be based either on the outlet pipework diameter of the relevant equipment, or the flow rate of waste water from the unit.

If you are unsure whether the grease removal system specified is sufficiently sized to handle your site’s waste, ask your contractor to see how they have sized the unit. While most contractors should do this as standard practice, and will be happy to provide you with the calculation, this is a worthwhile precaution, to ensure the equipment you are buying is fit for purpose, and that you won’t have to waste time and money purchasing a new grease trap/grease removal system later down the line, following an inspection or grease related problems arising. While an under-sized grease trap will fail to manage fat, oil and grease effectively, allowing sometimes substantial amounts to enter into the drainline, and leading to all the same problems as for a site with no grease trap at all, an over-sized trap will cost more to purchase, install and maintain, with spare part, service and overall costs likely to be substantially increased over time as a result.

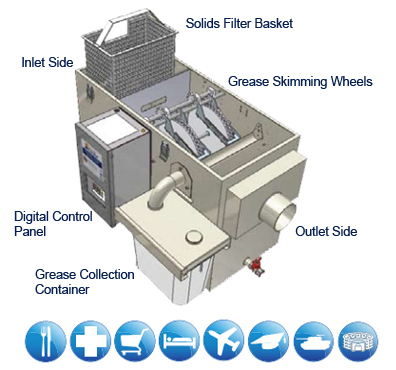

Once you are sure you have a correctly sized grease trap in your kitchen, all that remains is to ensure the unit is well maintained. This is achieved by carrying out daily maintenance on the grease trap to rinse and remove any food waste from filter baskets, preventing the basket from reaching capacity, or overflowing, and ensuring the peforated holes remain clear, to maintain the flow rate of waste water entering the grease trap. In the case of an automatic grease trap, it is important to clean skimming wheels and wiper blades, so they can continue to perform their function, without being overloaded with fat, oil and grease, preventing them functioning efficiently. Some automatic units will also contain a spray down bar, which is used to prevent any fat, oil and grease from solidifying along the edges of the grease trap.

As well as daily maintenance, it is also a requirement for most landlords and water authorities that grease traps receive a professional service/maintenance at least twice each year (although many busier sites will require more frequent visits). During this visit, an engineer or maintenance manager will empty, test and clean the interiors of the grease trap, to ensure there are no issues with the unit, change any parts in need of replacement, and dispose of any waste, which has been collected under license. While this can be done in house, it’s far from a pleasant job and a license will be required for proper waste disposal/recycling. It is advised that sites keep a record of both daily maintenance, and also of maintenance visits, which can be presented to landlords/water authorities upon request, to demonstrate that maintenance is being carried out. A maintenance log can also be particularly helpful, when assigning the daily maintenance task to individual staff, and making it immediately apparent if daily maintenance isn’t being carried out on any given day.

If your commercial kitchen is in need of a grease trap, get in contact with RGR today, either by giving us a call on 020 7221 6094, or by emailing info@rgrfacilities.co.uk and we can carry out a cost and commitment free site survey to determine a bespoke grease removal regime for your site.

For further facts, news & updates about grease traps, grease removal units & all things grease related, be sure to follow RGR on social media, either on facebook, linkedin or twitter, where we provide daily tips & updates about our goings on. We look forward to hearing from you.

Twitter: https://twitter.com/RGR_Facilities

Facebook: https://www.facebook.com/RGR-Facilities-Ltd-209575699167308/

LinkedIn: https://www.linkedin.com/company/rgr-facilities-ltd